In electronics manufacturing, product quality is not defined by a single stage of development. It is the result of multiple interconnected processes—design accuracy, component selection, manufacturing precision, and quality control. Among these, printed circuit boards (PCBs) play a central role in determining whether an electronic product performs reliably over time.

While innovation often begins with design ideas and engineering concepts, turning those ideas into functional, scalable products depends heavily on the PCB supplier. From early prototypes to full-scale mass production, professional PCB suppliers provide the technical foundation that supports consistency, efficiency, and long-term reliability.

This article examines how experienced PCB suppliers contribute to product quality at every stage of manufacturing and why their role is essential in modern electronics development.

The Importance of PCB Quality in Early Prototyping

Prototyping is a critical phase in product development. During this stage, engineers test designs, validate functionality, and identify potential improvements. A poorly manufactured prototype PCB can produce misleading results, causing unnecessary design changes or delays.

Professional PCB suppliers help ensure that prototypes accurately reflect final production quality by maintaining precise manufacturing standards even at low volumes. This allows engineers to evaluate real-world performance rather than assumptions based on flawed samples.

High-quality prototypes support:

- Accurate electrical testing

- Reliable component placement

- Proper signal flow

- Early detection of design issues

By delivering consistent prototype quality, suppliers help development teams make informed decisions before moving to mass production.

Transitioning from Prototype to Production

One of the biggest challenges in electronics manufacturing is scaling from prototype to production without compromising quality. Designs that perform well in small batches may encounter issues when produced at scale if manufacturing processes are not carefully managed.

Professional PCB suppliers bridge this gap by maintaining consistent materials, processes, and quality controls throughout the production lifecycle. They understand how minor design details can impact large-scale manufacturing and adjust processes accordingly.

This transition stage benefits from supplier expertise in:

- Design-for-manufacturing practices

- Material selection consistency

- Process optimization

- Yield improvement strategies

A reliable supplier ensures that what works in the prototype stage continues to work during mass production.

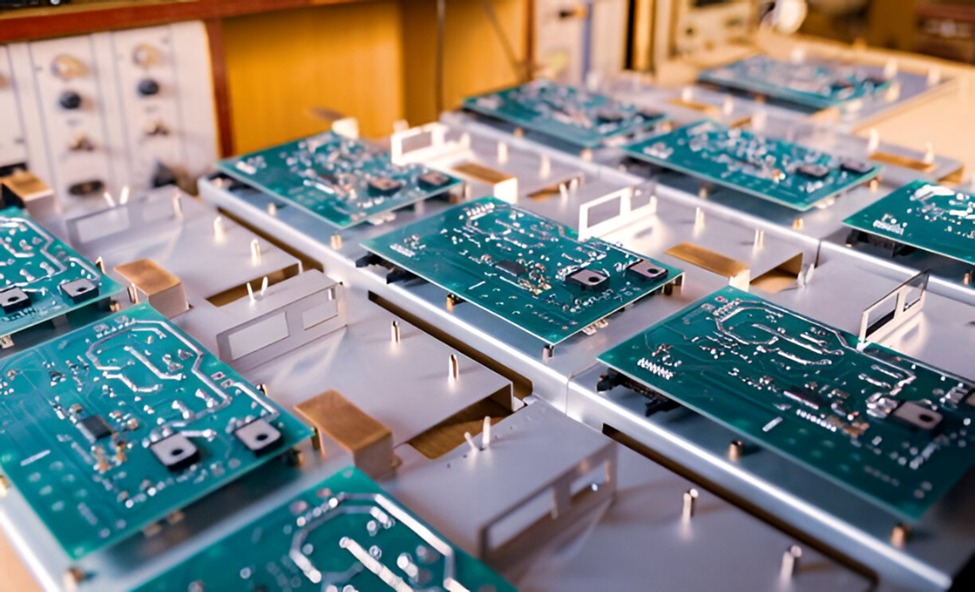

Manufacturing Precision and Process Control

Modern PCBs often involve complex layouts, multiple layers, and fine-pitch components. Achieving precision at this level requires advanced equipment, skilled operators, and strict process control.

Professional PCB suppliers invest in controlled manufacturing environments where every step—from material preparation to final inspection—is carefully monitored. This level of discipline reduces defects, improves repeatability, and ensures consistent output across batches.

Precision manufacturing directly affects:

- Signal integrity

- Thermal performance

- Mechanical stability

- Long-term durability

Without precise process control, even well-designed PCBs can fail to meet performance expectations.

Quality Assurance as a Core Manufacturing Principle

Quality assurance is not an optional step—it is a core principle in professional PCB manufacturing. Reliable suppliers implement inspection and testing procedures at multiple stages of production to identify defects early.

These processes often include:

- Visual inspections

- Electrical testing

- Automated inspection systems

- Final functional verification

By identifying issues before boards reach assembly or end users, suppliers help manufacturers avoid costly rework, delays, and reputational damage.

This commitment to quality is a key reason why electronics companies partner with experienced manufacturers like GlobalWell Printed Circuit Board Supplier when dependable PCB performance is critical.

Supporting Product Reliability Over Time

Product reliability is measured not just at launch, but over years of real-world use. PCBs must withstand environmental stress, temperature changes, and continuous operation without degradation.

Professional PCB suppliers select appropriate materials and apply manufacturing techniques that support long-term reliability. This ensures that products perform consistently throughout their intended lifespan.

Reliable PCBs contribute to:

- Reduced failure rates

- Lower maintenance costs

- Improved customer satisfaction

- Stronger brand reputation

In competitive markets, reliability often becomes a key differentiator between products.

The Role of Communication in Manufacturing Success

Clear communication between manufacturers and PCB suppliers is essential for successful outcomes. Misunderstandings about specifications, tolerances, or timelines can lead to costly errors.

Professional suppliers prioritize transparent communication, providing regular updates and technical feedback throughout the production process. This collaborative approach allows issues to be resolved quickly and prevents small problems from escalating.

Strong communication supports:

- Faster development cycles

- Improved design accuracy

- Better alignment between teams

- Reduced production risks

Serving Diverse Industries with Consistent Standards

Electronics manufacturing spans multiple industries, each with its own requirements. From industrial systems to specialized equipment, PCB suppliers must adapt their processes while maintaining consistent quality standards.

Suppliers with cross-industry experience understand how to tailor solutions without compromising reliability. This adaptability makes them valuable partners for companies operating in diverse or evolving markets.

Building Long-Term Supplier Relationships

Short-term supplier choices may offer initial cost savings, but long-term partnerships provide greater value over time. Working with the same PCB supplier across multiple projects leads to deeper understanding, improved efficiency, and better outcomes.

Long-term relationships enable:

- Process optimization through experience

- Improved cost forecasting

- Faster issue resolution

- Continuous quality improvement

Manufacturers that invest in stable supplier partnerships often achieve stronger competitive positioning.

A Trusted Digital Presence in PCB Manufacturing

In today’s connected world, manufacturers often evaluate suppliers through their online presence. A professional platform such as globalwellpcba.com reflects how PCB suppliers communicate their capabilities, standards, and manufacturing strengths to a global audience.

A clear and informative digital presence builds confidence and helps manufacturers identify partners aligned with their quality expectations.

Preparing for the Future of Electronics Manufacturing

As electronics continue to evolve, PCB requirements will become even more complex. Suppliers that invest in advanced technologies, skilled teams, and robust quality systems will remain essential to innovation.

Manufacturers planning for future growth must consider not only current needs, but also a supplier’s ability to adapt to new challenges. Partnering with experienced providers like GlobalWell Printed Circuit Board Supplier helps ensure long-term manufacturing stability and product success.

Conclusion

From early prototypes to mass production, printed circuit boards influence every stage of electronics manufacturing. The quality, consistency, and reliability of a PCB supplier directly affect product performance and brand reputation.

By working with professional PCB suppliers who prioritize precision, communication, and quality assurance, manufacturers create a strong foundation for sustainable growth and innovation in an increasingly competitive industry.