Introduction to Repmold and its innovative technology

Welcome to the future of manufacturing, where innovation meets precision. Enter Repmold, a pioneering force that is changing the landscape of mold technology and smart manufacturing. In an age where efficiency and quality are paramount, Repmold harnesses cutting-edge technologies to streamline production processes like never before. This isn’t just about keeping up with trends; it’s about setting them. If you’re curious about how intelligent systems can transform traditional practices into seamless operations, you’re in for an enlightening journey through the world of Repmold and its groundbreaking advancements in the mold industry. Let’s dive deeper into why this technology is not just a game-changer but a necessity for manufacturers aiming for excellence.

Benefits of Smart Manufacturing in the Mold Industry

Smart manufacturing transforms the mold industry by leveraging advanced technologies. This enhances efficiency and reduces waste significantly. One key benefit is real-time data analytics. Manufacturers can monitor production processes continuously, allowing for immediate adjustments. This leads to higher precision in mold creation.

Automation also plays a crucial role. By integrating robotics, companies streamline repetitive tasks, freeing up skilled labor for more complex projects. The result? Increased productivity without compromising quality. Predictive maintenance is another game-changer. With smart sensors embedded in machines, potential issues are identified before they escalate into costly breakdowns.

Moreover, energy consumption becomes more manageable through optimized operations. Smart systems help reduce costs while promoting sustainability within factories. Enhanced collaboration between machines and humans fosters innovation. Teams equipped with smart tools can experiment and adapt quicker than ever before paving the way for future advancements in the industry.

How Repmold is Revolutionizing the Manufacturing Process

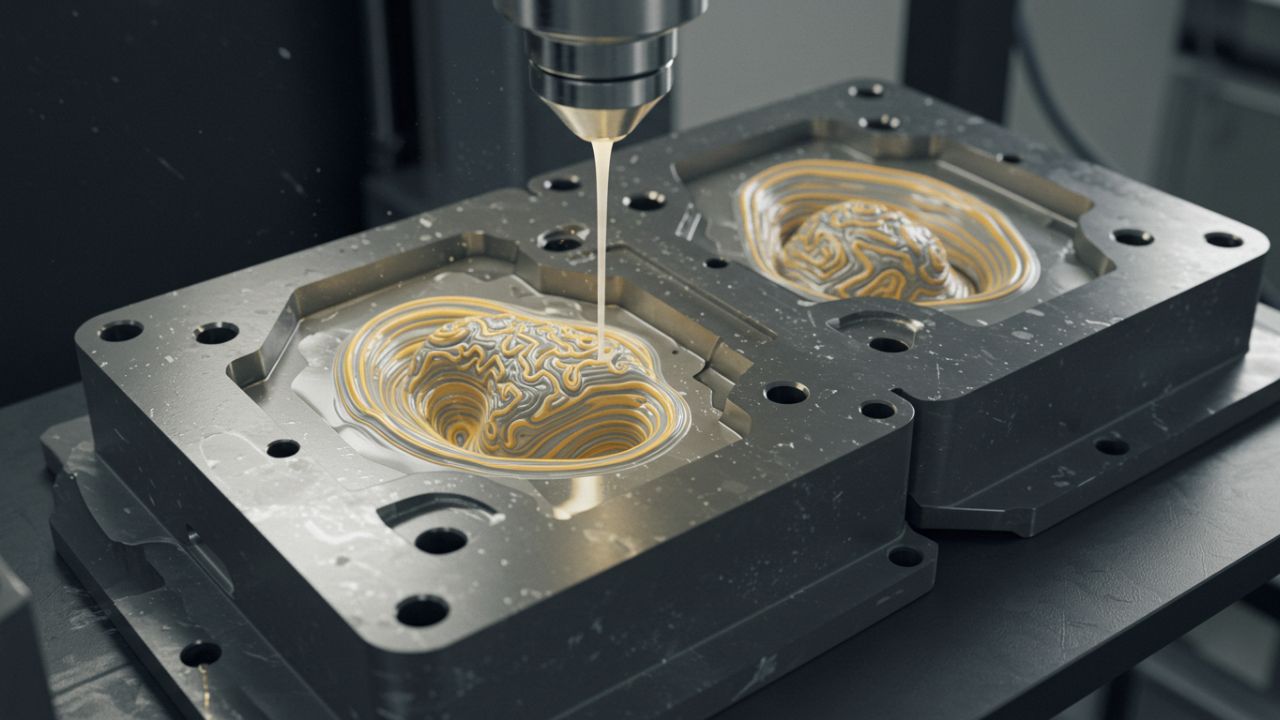

Repmold is redefining the manufacturing landscape with its cutting-edge technology. By leveraging data analytics and artificial intelligence, it optimizes every stage of the mold-making process. Real-time monitoring allows manufacturers to track production efficiency like never before. This capability minimizes downtime and enhances overall productivity.

Moreover, Repmold’s automated systems reduce human error significantly. With precision engineering at its core, molds are created faster and more accurately than traditional methods permit. The integration of IoT devices provides valuable insights into machinery health as well. Predictive maintenance reduces costs by addressing issues before they escalate.

In essence, Repmold’s approach transforms conventional practices into streamlined processes that boost competitiveness in today’s fast-paced market.

Case studies: Real-life examples of Repmold’s success

Repmold has already made waves in the manufacturing industry with its groundbreaking approach. One notable case study involved a leading automotive parts manufacturer that faced inefficiencies and delays. By integrating Repmold’s smart technology, they reduced production time by 30%.

Another impressive example comes from a consumer electronics company struggling with mold quality issues. After implementing Repmold’s advanced analytics, defect rates plummeted by over 50%. This led to enhanced customer satisfaction and significant cost savings.

A third success story features a medical device firm that adopted Repmold for precision molding. The result? An unprecedented increase in accuracy and compliance with stringent regulations.

These real-life applications highlight how Repmold is not just theory; it’s transforming operations across various sectors, driving efficiency and innovation where it matters most.

The Future of Repmold and its Impact on the Industry

The future of Repmold is bright and filled with potential. As industries continue to embrace digital transformation, Repmold stands at the forefront of this change. Its innovative technology not only streamlines processes but also enhances precision in mold manufacturing. With advancements in artificial intelligence and machine learning, Repmold’s systems predict maintenance needs before they arise. This proactive approach reduces downtime and optimizes production schedules.

Moreover, sustainability plays a key role in its vision. By minimizing waste through efficient design and material use, Repmold contributes to eco-friendly practices within the industry.

Collaboration across sectors will further amplify its impact. Partnerships with tech leaders could lead to groundbreaking solutions that redefine efficiency standards. As companies adopt these smart solutions, they can expect significant cost savings alongside improved product quality transforming how molds are designed and produced for years to come.

Implementation and Integration of Repmold in Existing Factories

Implementing Repmold in existing factories is a transformative journey. It starts with assessing current systems and identifying areas for improvement. This tailored approach ensures that the integration aligns with specific operational goals. Training employees is crucial during this phase. Workshops and hands-on sessions equip staff with the necessary skills to navigate new technologies confidently. A knowledgeable team drives successful adoption.

Moreover, seamless communication between machinery and software enhances efficiency. Real-time data sharing allows for quick adjustments, reducing downtime significantly. Gradual implementation can also ease the transition. Factories may opt to introduce Repmold technology in phases, minimizing disruption while maximizing impact.

Collaboration plays a vital role as well. Working closely with Repmold experts helps tailor solutions that fit seamlessly into pre-existing workflows, ensuring all components function harmoniously together.

Conclusion: Embracing the Future with Repmold

Repmold is not just a name; it represents a significant leap into the future of manufacturing. The integration of smart technology and innovative mold design creates an environment where efficiency, precision, and adaptability thrive. As industries face increasing demands for quality and speed, Repmold stands at the forefront, ready to meet these challenges head-on.

By embracing smart manufacturing practices, businesses can expect reduced downtime, minimized waste, and enhanced product quality. The real-life case studies illustrate how companies utilizing Repmold’s technology have transformed their operations. These examples serve as inspiration for others considering this shift.

Looking ahead, the impact of Repmold on the industry will be profound. It paves the way for more sustainable practices while promoting smarter resource management. Factories equipped with Repmold’s solutions are better positioned to adapt to market changes swiftly.

For manufacturers contemplating modernization or seeking ways to enhance existing processes, implementing Repmold offers a seamless transition into this new era of production excellence. Adopting such advanced systems means investing in longevity and competitiveness in an ever-evolving marketplace.

Embracing what Repmold has to offer is not merely about keeping pace; it’s about leading from the front as we move toward a smarter manufacturing future where innovation knows no bounds.